News

Ensure Confidence in Protective Coatings

What is Corrosion Testing?

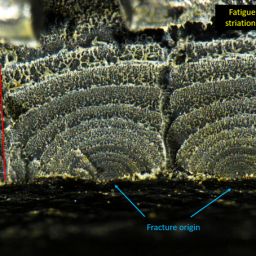

Corrosion testing is performed to determine any weaknesses of protective coatings when faced with challenging service environments.

Most commonly, these challenges are salt, humidity and extreme temperatures. For this reason, corrosion testing is commonly referred to as salt spray testing.

Simulating corrosive environments in a laboratory can identify issues with coating suitability and longevity.

It can also raise awareness to problems with coating

processes and coating materials.

For example, an area of poor coating thickness or a coating with substandard barrier pigments can be easily identified when performing corrosion testing.

How ExcelPlas can support your Project?

At ExcelPlas, our experts have corrosion testing facilities with the ability for the close control of pH, salt density, temperature, water purity and atomization rates.

This allows us to perform corrosion testing in accordance with a broad range of neutral salt spray standards.

Some of the most widely recognized standards ExcelPlas tests to include ASTM B117, ISO 9227 and RTCA-DO-160G.

Our product testing team are also able to perform bespoke corrosion tests to suit your requirements.

Their deep insights and technical understanding give your team confidence in your coatings and application methods.