News

Analysis of ACP Cladding Sample

Objective

To characterize the core components and determine the level of inert filler present in each sample.

Testing Undertaken

- Quantitative gravimetric ashing

- FTIR spectroscopy

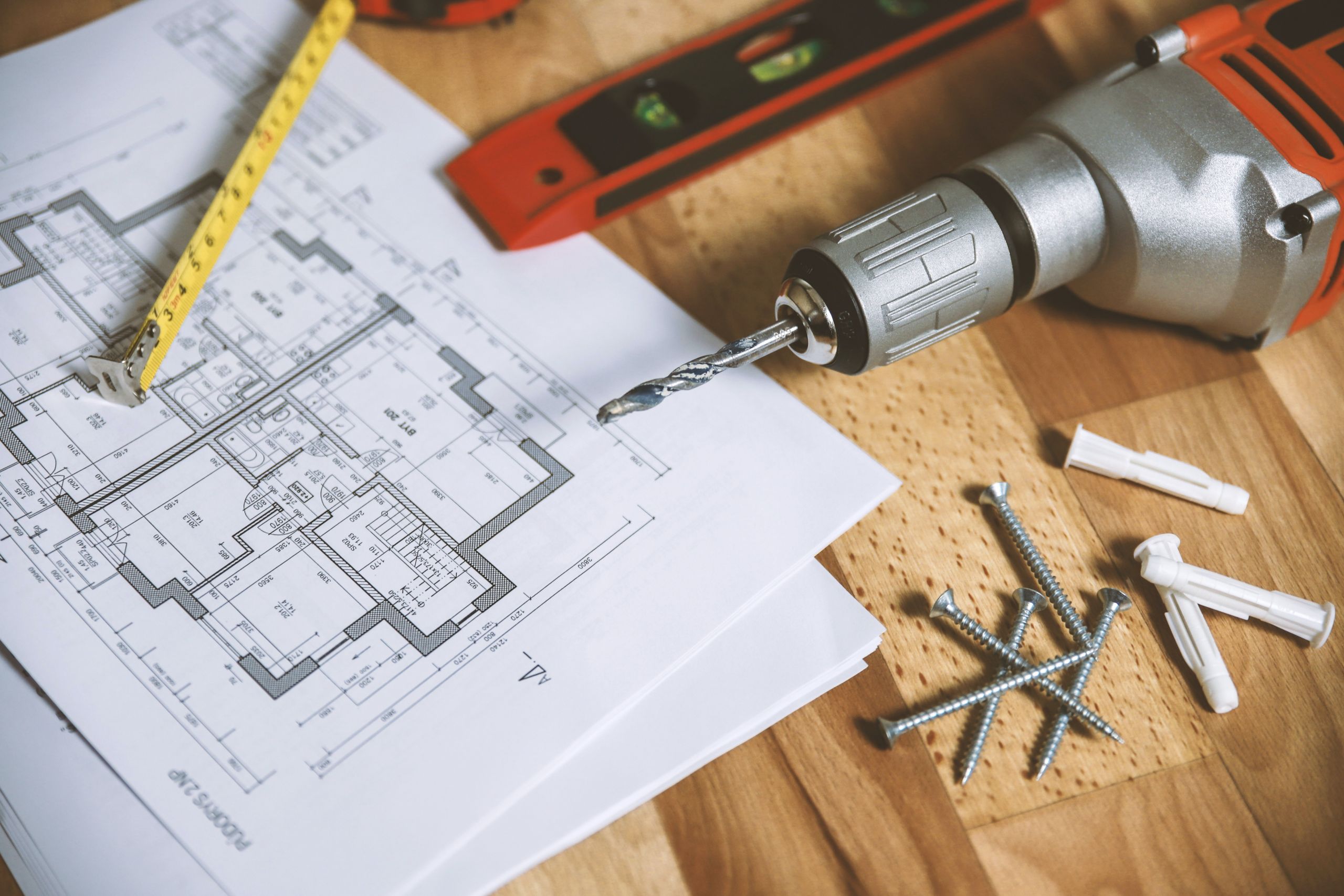

Figure 1. ACP sample for cladding testing (left).

FTIR Analysis

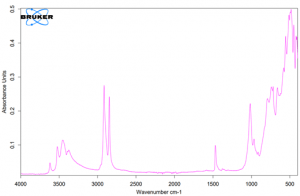

Fourier Transform Infrared (FT-IR) spectroscopy was used for ‘finger-printing’ for material identification of the polymer and filler components. The FT-IR analysis was performed according to ASTM E573 ‘Standard Practices for Internal Reflection Spectroscopy” using an Alpha Measurement Module by Bruker Optik see figure 2. Smaller samples of the core were cut from the larger sample. Spectra of the core were searched against an internal library database for identification.

Figure 3. FTIR spectrum of the cladding core indicating the presence of both polyethylene and aluminium trihydrate (note pentet of peaks around 3500 cm-1).

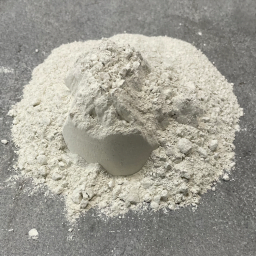

Ash Residue

Ashing residue testing was based on ASTM D 5630 – 13 “Standard Test Method for Ash Content in Plastics” using a muffle furnace. This technique enables quantification of the combustible and non-combustible fractions.

It was found that this ACP cladding core contained a mixture of of Polyethylene and Aluminium Trihydrate (ATH). Through quantitative gravimetric ashing the measured inert filler percentage of ATH and organic polymer percentage as PE was determined to be 71% and 29% respectively. Thus, categorising this sample as moderate to low fire risk and nominated as Category “B”.

ExcelPlas now performs Positive Material Identification (PMI) and Combustibility Rating (CR) on architectural cladding such as Aluminium Composite Materials ACM, Aluminium Composite Panels ACP, Expanded Polystyrene Panels (EPS), Polyisocyanuarate Foam Panels (PIC) and others.

We have extensive experience with testing of polymers and polymeric building materials.

As a Nationally Accredited Testing Laboratory, our technicians, equipment and quality system are monitored regularly for proficiency and compliance assuring that you can count on quality results every time.