News

Discussion on Potential Generation and Shedding of Microplastics from Geosynthetics

Authors

By GNA Editor | 29thth January 2023

This article explores the potential for microplastic generation stemming from geosynthetic civil engineering products.

Microplastics originate from a diverse array of sources, with polymer-based items being a ubiquitous presence in our daily lives. These encompass clothing, household articles, stationery, packaging materials, and even personal hygiene items like masks and gloves. While these items all carry the potential for microplastics, we will focus our attention on polymer-based civil engineering products.

The definition of microplastics isn’t always crystal clear, but it generally refers to plastic particles smaller than 3 mm but larger than one micron. Anything smaller is typically classified as nano-plastics. When categorizing the sources of microplastics, we distinguish between primary and secondary microplastics.

Primary microplastics are intentionally manufactured in small sizes for specific purposes, which isn’t applicable to the products we’re discussing today.

Secondary microplastics, on the other hand, arise from the deterioration of larger items. This is where we delve into how microplastics relate to civil engineering products.

The civil engineering products in question primarily include geogrids for reinforcement and geotextiles for separation and filtration. While these are designed for civil engineering and infrastructure development, the pivotal question is whether they introduce microplastics into the environment.

We are confident they do not significant contributors of microplastics into the environment, and here’s why:

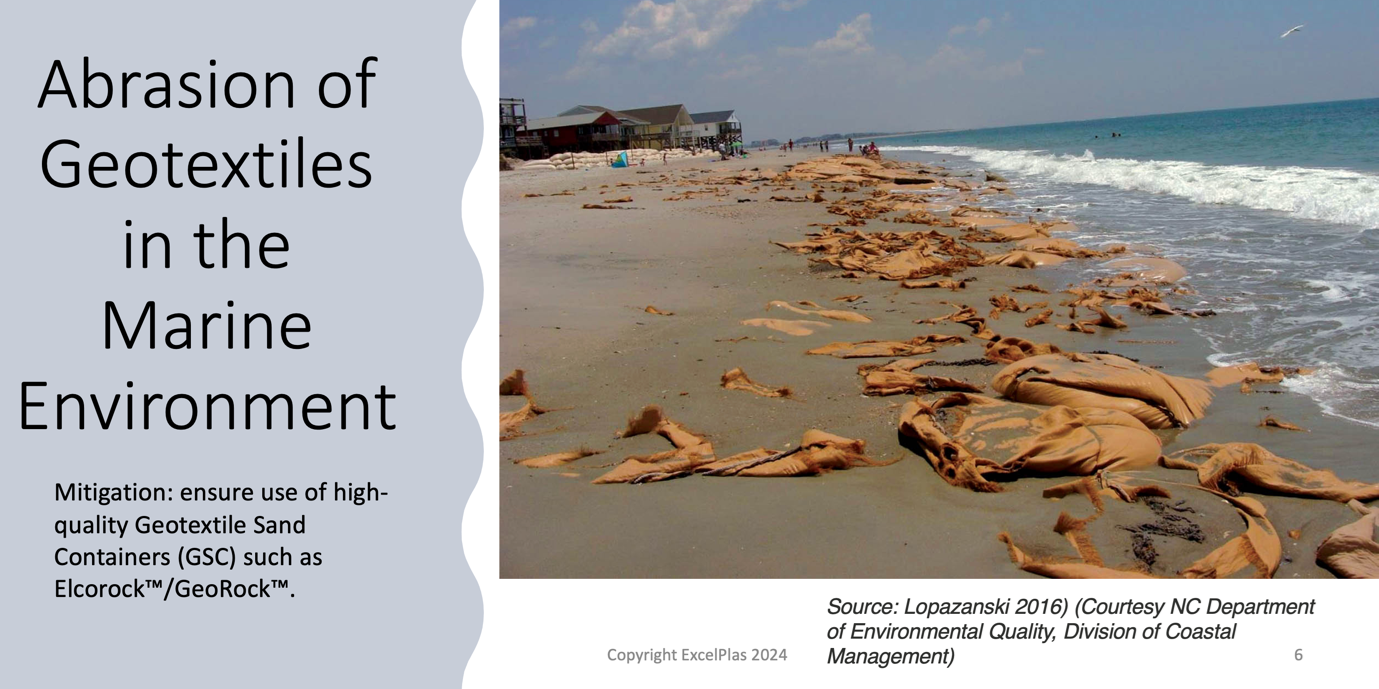

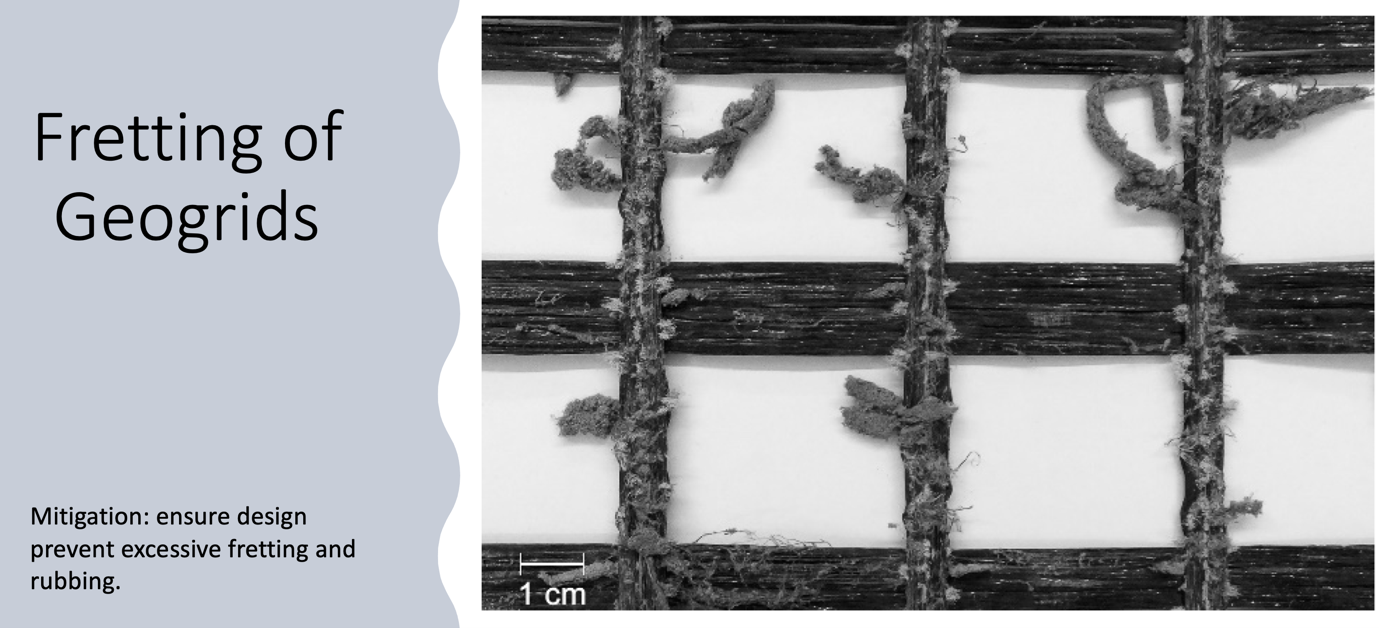

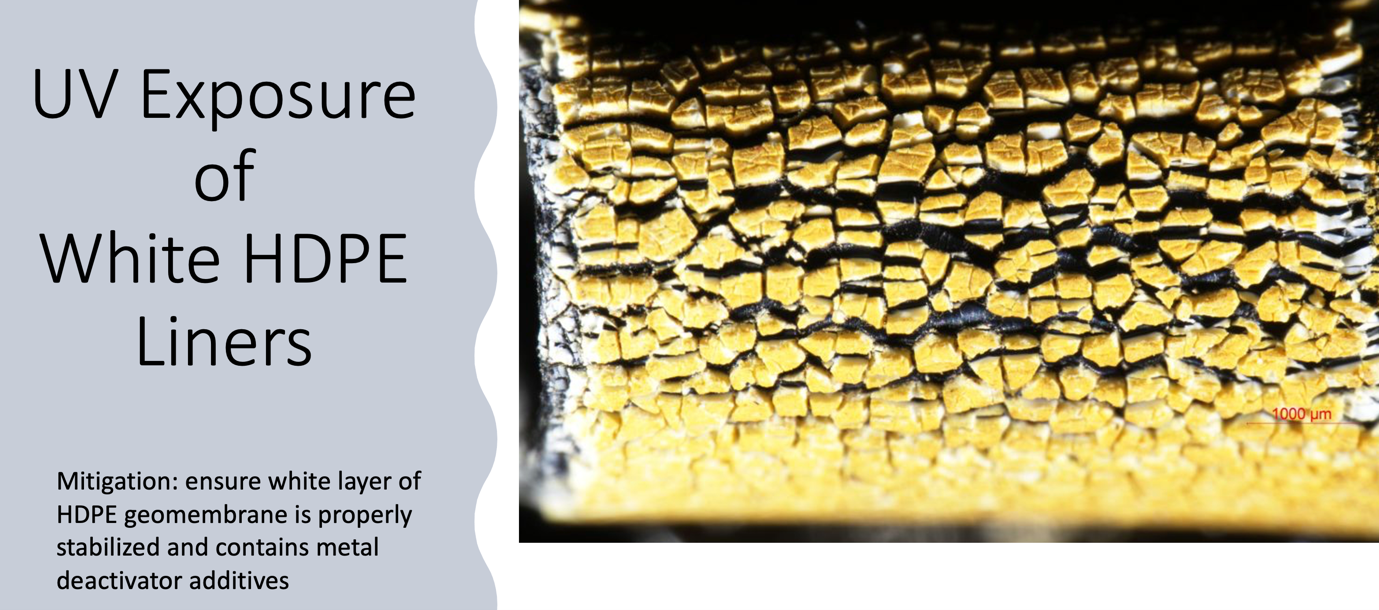

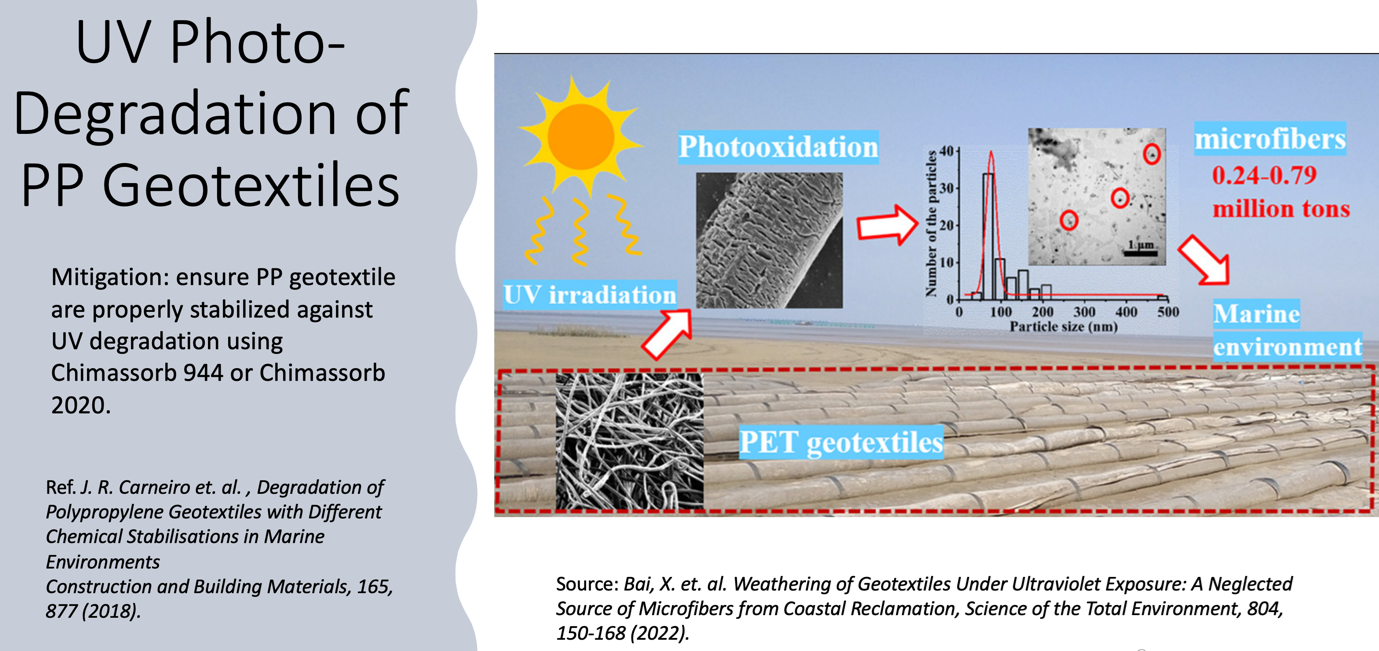

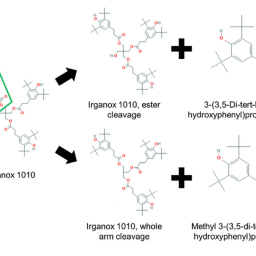

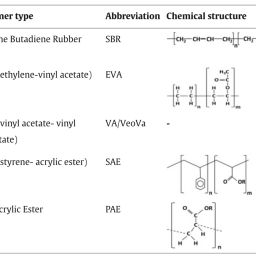

Firstly, polymer-based products degrade through two main mechanisms: physical abrasion and chemical or UV degradation. In the natural environment, physical abrasion occurs when these products rub against other surfaces, causing small plastic fragments to break off. Chemical or UV degradation, on the other hand, involves the product deteriorating chemically, leading to the liberation of small pieces.

These geosynthetics can be further categorized based on their usage, either below ground or above ground.

Below Ground Use:

The majority of these products are employed underground, where they are largely shielded from abrasion and UV exposure. Geogrids and engineering fabrics, in particular, are predominantly used below the ground. Apart from minimal abrasion during installation, which they are engineered to withstand, there is little to no further abrasion over their extended design life, which often exceeds 100 years. At the end of this design life, they can be recycled, making them environmentally friendly alternatives, especially when compared to traditional materials like quarried rock. When placed underground, exposure to hydrolysis or oxidation is minimal, ensuring that breakdown causing microplastics are not generated from abrasion or chemical degradation.

Above Ground Use:

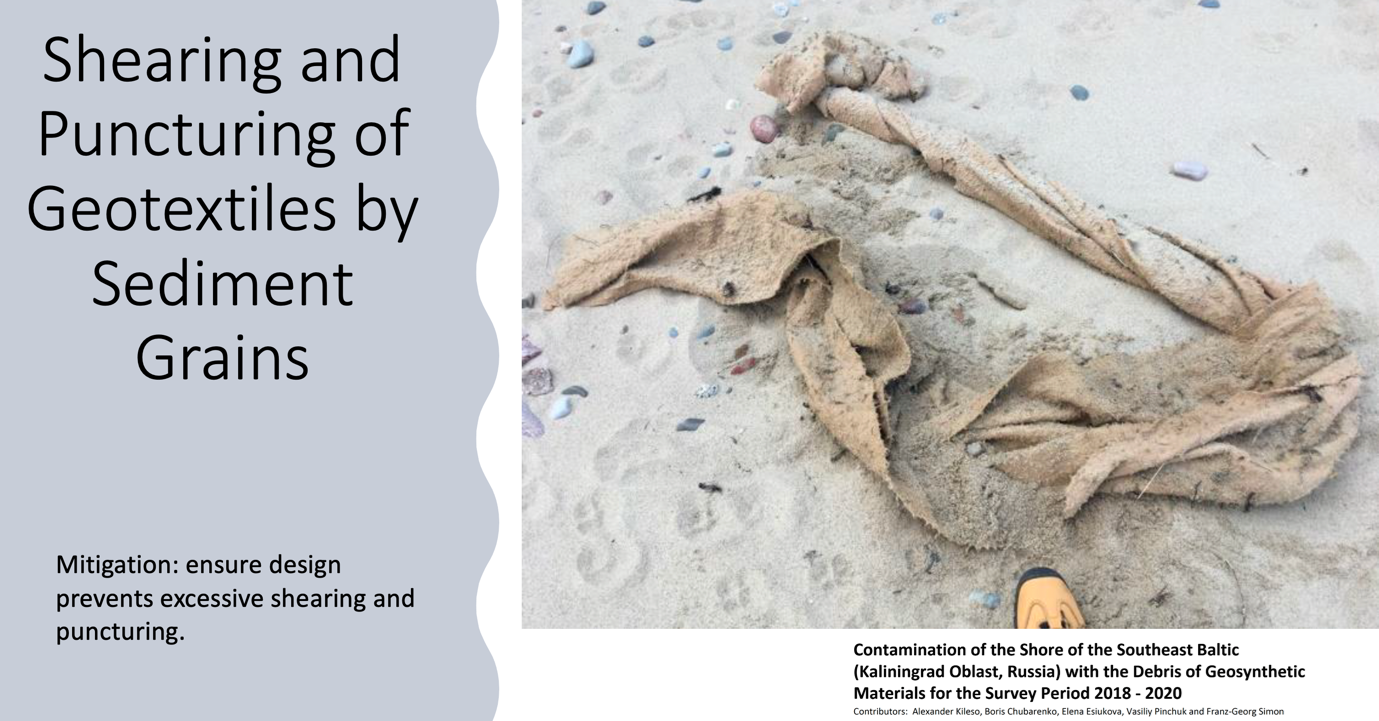

The situation differs when these products are used above ground. They are typically seen in two scenarios: geotextiles for temporary erosion protection on construction sites and erosion control matting. In these cases, there is a risk of abrasion and UV degradation.

To mitigate this, we design the products for above-ground use in two ways: by using UV-protected materials and by calendering the surface. Calendering involves applying heat to bind the fibers together, preventing them from breaking off and entering waterways. However, it’s essential to remember that using drainage products designed for underground use on the surface can pose a risk of microplastic generation.

For erosion control matting, some products utilize biodegradable materials like coconut matting, which completely degrade if the fibers enter the environment. Others employ UV-stabilized polymer-based carrier layers and biodegradable materials above ground to prevent the formation of microplastics. Additionally, products like turf matting and erosion control mats are embedded into the root zone, minimizing exposure to sunlight.

In summary, engineered long-term plastics differ significantly from single-use plastics. They are designed to last for well over a century and are engineered into projects to prevent microplastic generation in the environment.

Furthermore, these engineered polymer-based products contribute to substantial resource conservation and offer significant carbon-friendly benefits when compared to traditional materials like quarried rock.

References

‘Microplastics in the environment’

https://geosyntheticsmagazine.com/2024/01/22/microplastics-in-the-environment/