News

Advancing Geosynthetics: The Innovation of Cement Coated Geocomposites (CCGC)

Authors

By GNA Editor | 11th December 2023

The world of construction and civil engineering is constantly evolving, driven by the need for more efficient and cost-effective solutions. One such innovation that has been gaining traction in recent years is the use of Cement Coated Geocomposites (CCGC). These hybrid materials combine the versatility of geosynthetics with the binding power and durability of Portland cement, opening up new possibilities in soil reinforcement and stabilization.

Introduction

Geosynthetics have long been used in various construction applications, from retaining walls to erosion control. However, their effectiveness in reinforced soil structures has often been limited by factors such as pullout capacity and interface properties. Traditional geosynthetics, while useful, may struggle to provide the required anchorage length for reinforcements in certain scenarios.

Portland cement, known for its widespread availability and affordability, presents an exciting opportunity to enhance geosynthetics’ performance in soil reinforcement. This innovation involves the application of thin layers of cementitious coatings onto the surfaces of ordinary planar geosynthetics, such as geogrids and geotextiles. These coatings are fortified with polymer modifiers, called Redispersible Polymer Powders (RPPs), to impart flexibility and crack resistance.

The Role of Redispersible Polymer Powders (RPPs)

RPPs are well-established modifiers in the realm of cement and concrete. They offer several advantages when incorporated into cementitious coatings:

- Strength Enhancement: RPPs improve the compressive strength, plasticity, abrasion resistance, and flexural strength of cement.

- Flexibility: Depending on the cement-polymer ratio, RPPs can introduce a degree of flexibility to the cementitious coating, reducing the elastic modulus.

- Impermeability: The polymer coating closes the pores and crevices of the hardened cementitious layer, making it impermeable to fluids like water and alkali.

- Improved Liquidity: RPPs enhance the liquidity of the cementitious coating, making it easier to work with.

- Water Retention: These modifiers also impart water retention properties to the cementitious coating allows full cure.

- Slip and Impact Resistance: RPPs provide slip and impact resistance, contributing to crack prevention.

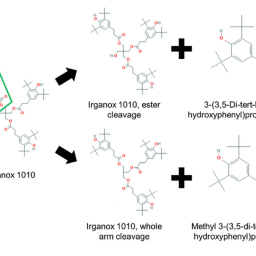

Poly (vinyl acetate-vinyl versatate) or VA/VeoVa is one such effective RPP. The inclusion of the versatate group adds long α-alkyl molecule side chains to the polymer, resulting in superior alkali resistance. Another option is Poly (styrene – acrylic ester) or SAE, an acrylic polymer that can modify cementitious coatings effectively. As the SAE/cement ratio increases, water-reduction, water retention, flexural strength, and waterproofing properties also improve.

Structures of common PRR are shown below.

Formulating Cementitious Coatings for Geotextiles

A crucial aspect of creating Cement Coated Geocomposites (CCGC) is the formulation of cementitious coatings for geosynthetics. While specific formulations may vary depending on the application, a typical formulation for a cementitious coating for geosynthetics might include the following:

These formulations are designed to enhance the flexibility, adhesion, durability, mechanical properties, and water tightness of the cementitious coating on the geosynthetic substrate.

Benefits of CCGC

The resulting CCGC presents several advantages:

- Enhanced Interface Properties: CCGC provides a rough surface with a higher interface friction angle compared to ordinary planar geosynthetics. This enhanced interface makes it particularly useful when high pull-out capacity is required for reinforced soil structures.

- Mechanical and Chemical Soil Stabilization: CCGC combines both mechanical and chemical soil stabilization methods. This dual approach ensures robust soil-geosynthetic interactions.

- Cost-Effective Anchorage: The high pull-out capacity of CCGC makes it an ideal reinforcement material, especially when the required anchorage length for reinforcements cannot be easily provided.

Conclusions

The development of Cement Coated Geocomposites (CCGC) represents a significant advancement in the field of geosynthetics and soil reinforcement. By combining the versatility of geosynthetics with the binding power of Portland cement and polymer modifiers, CCGC offers improved pullout capacity and enhanced interface properties. This innovation opens up new possibilities for cost-effective and efficient soil stabilization and reinforcement in construction projects.

Research in this area continues to evolve, with practical applications already demonstrating promising results. The ability to utilize readily available materials like Portland cement and low-cost geosynthetics makes CCGC a practical and accessible solution for various construction and civil engineering challenges.

In conclusion, the introduction of CCGC stands as a testament to the industry’s commitment to innovation and the relentless pursuit of better, more efficient construction solutions. As technology and research continue to progress, we can expect further refinements and broader applications of Cement Coated Geocomposites in the construction landscape.